What is Waste-to-Energy

FAQ – Here are some answers to the most frequent questions about Waste-to-Energy

Waste-to-Energy plants burn household and similar waste that could not be prevented or recycled.

From this incineration process the plants recover energy. This can be in the form of steam, electricity or hot water. The electricity is fed into the grid and distributed to the end-users; the hot water, depending on local infrastructure can be sent to a nearby district heating (or cooling) network to heat (or cool) homes, hospitals, offices etc., and the steam can be used by the nearby industry in their production processes.

Waste-to-Energy is a hygienic method of treating waste, reducing its volume by about 90%.

Modern European Waste-to-Energy plants are clean and safe, meeting the most strict emission limit values placed on any industry set out in the EU Industrial Emissions Directive.

Waste-to-Energy fulfills two main important roles:

Additionally, the energy produced in Waste-to-Energy plants also contributes to climate protection and security of energy supply, by replacing fossil fuels that would have been used to produce this energy in conventional power plants.

Waste prevention, re-use and recycling are fundamental to achieving a circular economy.

Waste-to-Energy goes hand in hand with high-quality recycling. It is an essential and complementary part of a sustainable circular economy and an indispensable part of the solution to waste management.

The problem we are tackling is how to deal with residual waste that cannot be recycled? This is the waste that contains mixed materials, substances of concern or simply has been recycled too many times. As the EU Policy rightfully restricts exports of waste that have harmful environmental and health impacts on third countries, we are left with the options of disposal or recovery.

We urgently need to boost recycling and in parallel limit waste disposal. Waste-to-Energy treats the non-recyclable residual waste that would others be landfilled and prevents illegal dumping avoiding potential groundwater, soil and marine contamination and above all the creation of methane emissions. The Global Methane Pledge highlights the critical importance of reducing methane to limit global warming.

Waste-to-Energy instead recovers.

So why burning waste? Because when we treat non-recyclable waste in an environmentally safe way, waste becomes a resource; a reliable, clean resource that we can harness.

There are many everyday waste items made of mixed or dirty materials which will be very difficult to recycle, e.g. sponges, gift and candy wrappings, toothbrushes, old shoes, vacuum cleaner bags, greasy food packaging, etc. There are also certain other wastes that should not be recycled for hygienic reasons, for example some sanitary products. In addition, there are recycling residues and materials that will still be degraded due to repeated recycling or ageing. Others will be polluted with substances of high concern, for example heavy metals or flame retardants.

What can we do with the waste that remains after sorting and recycling? Waste to-Energy helps to mitigate the climate impact of this waste by:

Europe still landfills almost 60 million tonnes of municipal waste annually.

When we take into account commercial and industrial waste, the total figure amounts to ca. 100 million tonnes of non-inert waste per year. The Intergovernmental Panel on Climate Change (IPCC) says that “Compared to landfilling, waste incineration and other thermal processes avoid most GHG generation, resulting only in minor emissions of CO2 from fossil C sources.”

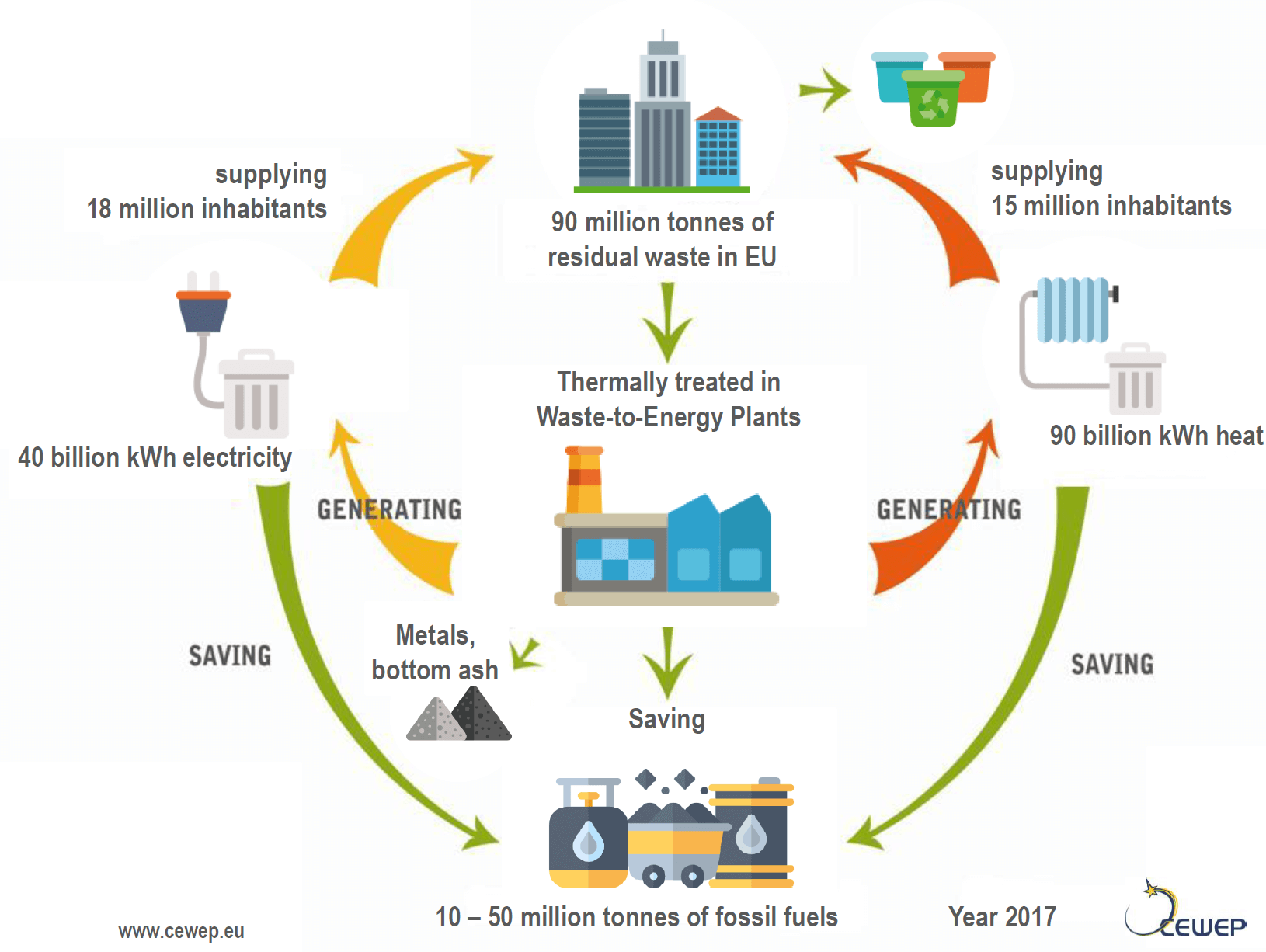

Currently, Waste-to-Energy Plants in Europe can supply 18 million inhabitants with electricity and 15.2 million inhabitants with heat. This is based on 90 million tonnes of remaining household and similar waste that was treated in 2015 in Europe.

Currently, Waste-to-Energy Plants in Europe can supply 18 million inhabitants with electricity and 15.2 million inhabitants with heat. This is based on 90 million tonnes of remaining household and similar waste that was treated in 2015 in Europe.

Depending on the fuel you replace – gas, oil, hard coal or lignite – between 10 – 49 million tonnes of fossil fuels emitting 24 – 49 million tonnes of CO2, would not need to be used by conventional power plants to produce this amount of energy.

According to the EU legislation the biodegradable fraction of municipal and industrial waste is considered biomass, thus a renewable energy source. The energy output from Waste-to-Energy plants is about 50% renewable.

Waste-to-Energy technology is one of the most robust and effective alternative energy options to reduce CO2 emissions and to save limited fossil fuel resources used by traditional power plants.

Thanks to the installation of complex flue gas cleaning systems in modern Waste-to-Energy facilities, dioxin emissions have been reduced significantly in the past 30 years. The Waste-to-Energy sector is one of the most strictly regulated industrial sectors in Europe, resulting in a share of less than 0.2% of the total industrial dioxin emissions. For example, in Sweden the sector’s emissions dropped from 100 g in 1985 to less than 1 g in 2015 while the amount of thermally treated waste more than doubled in the same period.

The European Waste-to-Energy plants carefully monitor their emissions and impacts on the environment during different operating stages. An in-depth overview of current monitoring methods in place can be found in the CEWEP report on Dioxins and Waste-to-Energy: State of the Art. Extensive research on health and environmental impact has been carried out and the sector’s impact is considered insignificant due to the low emission levels.

You can find more reports and studies on Waste-to-Energy in the Health and Environment section of our website.

The residual waste treated in Waste-to-Energy plants is burned under controlled conditions, reducing the volume of the waste by about 90%.

In a Waste-to-Energy plant the bottom ash is collected at the end of the furnace’s grate. It consists of non-combustible materials, and is the residual part from the incineration of waste. Even if the waste was sorted before hand, there are metals found in it. Both ferrous metals and non-ferrous metals can be taken out of the bottom ash and recycled. After the metals are taken out, the rest of the ashes, which are like gravel or sand, are stored for a period before being used in road construction or as a covering layer on landfill sites.

Waste incineration concentrates the environmentally harmful substances (lead, cadmium, mercury, etc.) which were already present in the waste in the flue gas cleaning residues. This makes further handling easier: these substances can be better managed and safely disposed of. The residues from the flue gas cleaning system amount to 3-4 % of the mass of the waste entering the plant.

These residues are collected after the filtration process and are carefully stored to ensure no escape of the material into the local environment. The material is then transported in sealed containers to hazardous landfill sites, to treatment plants or salt mines. These sites are fully contained so that the material cannot leach out into the environment.